The Only Guide for Recycling Lives Services

The Only Guide for Recycling Lives Services

Blog Article

The Single Strategy To Use For Recycling Lives Services

Table of ContentsRecycling Lives Services for DummiesFascination About Recycling Lives ServicesMore About Recycling Lives ServicesSome Of Recycling Lives ServicesRecycling Lives Services for Beginners10 Simple Techniques For Recycling Lives Services

E-waste recycling is a lot more challenging than traditional waste recycling. Usually, the primary step of the recycling procedure is hand-operated sorting. Once e-waste is gathered and delivered to the recycling centers, employees sort the e-waste right into categories according to their kinds and models. All electronic gadgets will certainly be checked out, and of which the components that are still practical will be drawn out to be recycled; they can either be marketed as specific components or be incorporated to form a new phone or computer system (recycling lives services roro hire).

Below, e-waste is thrown right into an enormous maker and is shredded into little pieces, but prior to that, it should initially experience a procedure called de-manufacturing, which refers to the activity of taking apart an item right into components. https://rcyclng1vssvc.carrd.co/. This procedure is to eliminate all the potentially harmful materials in electronic tools that will certainly destroy the maker or infect the environment when disposed into land fills

Rumored Buzz on Recycling Lives Services

Next, the waste is more separated with water. At this phase, almost every little thing leftover are non-magnetic products; they will experience one more maker full of water, where materials with a low family member density, primarily plastic, will certainly move, while various other products, like glass, will certainly sink. Ultimately, before recycled materials are sold, is to inspect if there are any type of remaining important products adhered to the plastic.

Recycling Lives Services Things To Know Before You Buy

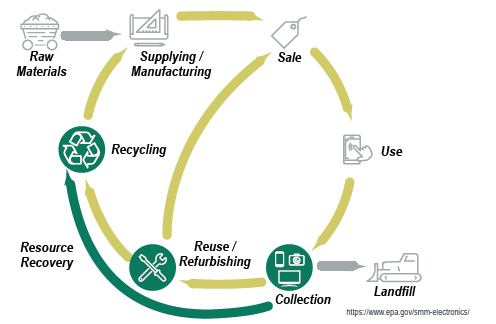

Reusing e-waste not just protects against poisonous materials from entering our bodies and into the setting, yet the procedure likewise minimizes the damaging environmental impacts developed by the extraction and mining of virgin materials. The prospective financial advantages that can be derived from this industry are substantial. The disposed of e-waste in 2019 alone was worth greater than US$ 57 billion.

Computers and electronic tools are made from numerous kinds of plastic, steel, glass and precious metals. Our objective when reusing electronics is to separate the different products from each various other. The "product" we generate from recycling is tidy separated streams of recycled plastic, iron, steel, copper, light weight aluminum, glass and precious metals.

2-1/2 minute video clip reveals electronics being reused at a SLS center. The customer records we are able to produce depends on how devices is taken care of prior to being reused.

The Of Recycling Lives Services

Our major reusing websites are outfitted with automated industrial shredders, conveyor systems and sorting devices. This first step prepares the e-waste to start the process of dividing plastic parts from steel, copper, light weight aluminum, glass and various other commodities.

After shredding, the conveyor belts press the e-waste through magnets, eddy currents, infrared video cameras and air jets. These modern technologies arrange out various product kinds and different arranged product from the e-waste stream. Iron and steel is divided from the e-waste, then aluminum, copper and circuit card are separated. After the mass metal is gotten rid of, the e-waste stream, which is currently mostly plastic, is additional divided into ABS from polystyrene plastic.

7 Simple Techniques For Recycling Lives Services

Separating Iron and Steel from e-Waste After shredding, conveyor belts transfer the shredded computers and e-waste under an effective magnet, which divides iron and steel from the shredded e-waste (recycling lives site here services waste electronics). The steel and iron are gathered in pallet sized bags and planned for sale as recycled asset materials. Dividing Light Weight Aluminum, Copper and Circuit card from e-Waste After passing under the magnet, the e-waste remains to move via the conveyor belts via additional mechanical separators

A visual examination and hand sorting enhances the high quality of the removed products. The apart streams of aluminum, copper, and circuit card are accumulated in pallet sized bags and prepared for sale as recycled commodity materials. Advantages of Recycling Recycling vs - https://rcyclng1vssvc.blog.ss-blog.jp/2024-09-28?1727478412. Virgin Product The separated assets are utilized to make future generation items

Making use of recycled material in the manufacturing of brand-new items has benefits that go far beyond product reuse. It lowers pollution and carbon emissions, decreases energy and water consumption and keeps useful products out of garbage dumps. As each commodity is separated from the e-waste stream, the product is collected in pallet sacks or huge cardboard boxes and shipped to one more cpu or directly to a manufacturer.

All about Recycling Lives Services

It reduces pollution and carbon emissions, minimizes energy and water intake and keeps valuable products out of garbage dumps. SLS is at the leading edge of establishing ingenious e-waste reusing services.

Customers can acquire fewer things while reusing and recycling extra. Companies can construct items developed to last, not to be replaced, and to be recycled.

Report this page